Belt Conveyor Concrete Batching Plant Systems: Optimal Efficiency and Superior Performance

At SHENGMAO, we take immense pride in offering the finest belt conveyor concrete batching plant that is designed to deliver optimal efficiency and superior performance. As a leading provider in the industry, we understand the importance of high-quality equipment to ensure seamless operations and maximize productivity in the construction field.

In modern construction, in order to improve the efficiency of concrete transportation and pouring, concrete mixer trucks with conveyor belts or concrete conveyor belt trucks are often used. This type of vehicle can not only ensure the quality of concrete, but also directly place the concrete to the required location through its integrated conveying system, greatly improving the efficiency of work. In addition, concrete batching computer systems are also used in conjunction, which can accurately control the proportion of concrete to ensure the stable and reliable quality of each batch of concrete. At the same time, independent concrete conveyor systems also play an important role in large projects. They can work in conjunction with concrete mixer trucks to achieve continuous transportation of concrete over long distances or at high altitudes to meet the needs of complex construction environments. The application of these equipment and technologies indicates that the construction industry is moving towards a more automated and efficient direction.

Introduction

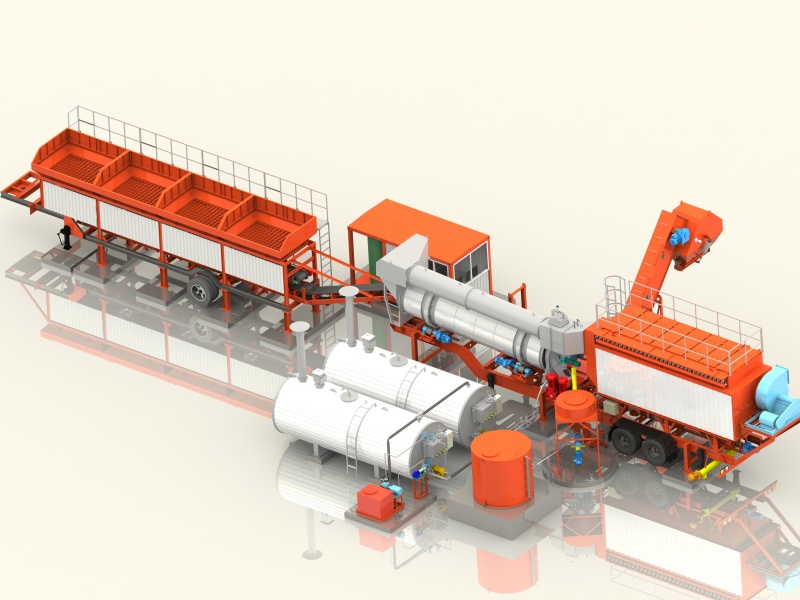

The belt conveyor concrete batching plant is a versatile and indispensable asset for any construction project. With its advanced technology and robust design, this plant has revolutionized the way concrete is produced and transported on-site. Whether it's a large-scale infrastructure project or a smaller residential construction, our belt conveyor concrete batching plant stands out as the ideal solution. Belt conveyor concrete batching plant is usually used for commercial concrete supplying business or big projects where huge amount high-quality concrete is needed. For Belt Type Concrete Batching Plant, each aggregate has its own scale, so the weighing accuracy and efficiency is remarkably improved. With the help of transitional hopper, the working efficiency of the whole batching plant can be 15% higher than that of the skip hoist type of batching plant. Belt conveyor concrete batching plant is equipped packing exterior for aggregate loading belt and mixing tower; Both cement silo and mixing tower have their own filter system. These measures ensure the operation of the whole batching plant is environment friendly. For belt conveyor concrete batching plant, we have 60m3/h, 90m3/h, 120m3/h, 180m3/h, 240m3/h.

Concrete conveyor systems are an invaluable tool on any construction site. These systems streamline the process of moving concrete from the mixing plant to the desired location, reducing labor costs and increasing productivity. They are particularly useful for large-scale projects where speed and precision are crucial, offering a reliable and continuous flow of concrete. For those operating a belt conveyor concrete batching plant, the integration of a conveyor system can significantly enhance operational efficiency. These plants utilize belt conveyors to transport raw materials and mixed concrete, ensuring a seamless and uninterrupted workflow. The use of belt conveyors minimizes the risk of material segregation and ensures consistent quality in the produced concrete. This system is ideal for high-volume production and is known for its durability and low maintenance requirements.

Welcome to contact us for details and quotations.

Details

1. Belt conveyor concrete batching plant is a common type of concrete batching plant, it is usually used for medium and big projects. It is composed of the following parts:

1) independent weighing aggregate batcher;

2) concrete belt conveyor systems (if your space is enough, flat belt will be used; if not, bucket belt will be used): We've been custom manufacturing conveyor systems, so no one can match our knowledge and experience, and we can design a concrete conveyor for your company to meet the unique challenges of moving concrete. We will consider factors such as the size of your facility, the location the conveyor will occupy, the size of your workforce, and the load the conveyor will be subjected to. And, because reliability is critical in industrial environments, SHENGMAO can design concrete conveyors that can operate smoothly under extreme conditions

3) twin-shaft concrete mixer, planetary concrete mixer;

4) water, cement and additive scales;

5) cement silo;

6) screw conveyor;

7) penumatic system;

8) packing exterior (protecting the environment)

9) fully automatic computer control system.

2. Advantages of belt conveyor concrete batching plant:

1) high production efficiency;

2) environment-friendly;

3. Details of our belt conveyor concrete batching plant

Concrete Conveyor Notes:

The conveyor belt should not be too long to avoid mixing changes

Inputs and Outputs: Measures should be taken to avoid mixing problems and keep mixing uniform (use a cement mixer or funnel)

Conveyor: Use a specific scraper or cleaner followed by a high-pressure jet

Oblique belt: consider water loss during conveying

A Concrete Belt is ideal for a variety of applications

Includes: Dams, Caissons, Wind Turbine Foundations, Bridge Decks, Backfills, Pad Casting, Environmental, Warehouse Slabs, Foundations, Foundations, Inclined and Outdoor Slabs

The concrete batching plant industry has seen significant advancements, especially with the integration of efficient belt conveyor concrete batching plants. These facilities are designed to handle large volumes of materials with precision, ensuring that every batch of concrete meets strict quality standards. A critical component of these systems is the batching plant conveyor belt, which plays an indispensable role in moving aggregates and other ingredients from storage to the mixing area. The conveyor belt batching plant design allows for continuous operation, minimizing downtime and increasing productivity. Operators benefit from the streamlined workflow that comes from having a robust concrete conveyor system in place. Furthermore, modern concrete conveyor belts come equipped with features that enhance safety and durability, making them a reliable choice for any construction project.

Innovations in concrete belt conveyor technology have revolutionized how concrete is transported on-site. These conveyors provide a cost-effective solution for moving materials over long distances or difficult terrains without compromising on efficiency. A well-designed concrete conveyor system can significantly reduce labor costs while improving the speed at which concrete can be delivered to its final location. For projects requiring flexibility, a mobile aggregate feeding conveyor offers the advantage of being easily relocatable, allowing it to adapt to changing site conditions. When selecting a concrete conveyor, contractors must consider factors such as capacity, distance, and environmental impact to ensure they choose the most suitable equipment for their needs. Reliable concrete conveyors contribute to the overall success of construction endeavors by maintaining a steady flow of materials.

Customization is key when it comes to choosing the right conveyor belt for concrete applications. Whether it's a stationary or mobile setup, the ability to tailor a concrete conveyor system to fit specific requirements can make all the difference in project outcomes. We now offer a wide range of options, from standard models to bespoke solutions that cater to unique challenges faced on-site. This flexibility ensures that each concrete conveyor systems installation can meet performance expectations and comply with local regulations. As the demand for high-performance infrastructure continues to grow, so does the importance of investing in dependable concrete belt conveyor technology. By doing so, companies can achieve greater operational efficiencies and maintain a competitive edge in the market.

Belt conveyor Concrete Batching Plant

| HZS60 Belt Conveyor Concrete Batching Plant Capacity: 60 m3/h Concrete Mixer: JS1000 Aggregate Batcher: PLD1600 Control System: Computer Control |

| HZS90 Belt Conveyor Concrete Batching Plant Capacity: 90 m3/h Concrete Mixer: JS1500 Aggregate Batcher: PLD2400 Control System: Computer Control |

| HZS120 Belt Conveyor Concrete Batching Plant Capacity: 120 m3/h Concrete Mixer: JS2000 Aggregate Batcher: PLD3200 Control System: Computer Control |

| HZS180 Belt Conveyor Concrete Batching Plant Capacity: 180 m3/h Concrete Mixer: JS3000 Aggregate Batcher: PLD4800 Control System: Computer Control |

| Model | HZS60 | HZS90 | HZS120 | HZS180 |

| Production capacity (m3/h) | 60 | 90 | 120 | 180 |

| Concrete mixer | JS1000 | JS71500 | JS2000 | JS3000 |

| Aggregate feeding mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor |

| Aggregate size (mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Discharging height(m) | 4.1 | 4.1 | 4.1 | 4.1 |

| Aggregate weighing accuracy (%) | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Fly ash weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy (%) | ±1% | ±1% | ±1% | ±1% |

| Total weight(T) | 28 | 40 | 65 | 88 |

| Total power(T) | 110 | 156 | 200 | 260 |

| Control system | Computer | Computer | Computer | Computer |

4. Cases of our belt conveyor concrete batching plant

1) HZS60 concrete batching plant to Philippines

5. Videos of our belt conveyor concrete batching plant

Enhanced Efficiency through Innovative Design

Our belt conveyor concrete batching plant is meticulously engineered to enhance efficiency and streamline the production process. The plant is equipped with a reliable and durable conveyor belt system, which allows for the efficient transport of aggregates, cement, and water to the mixer. This eliminates the need for manual handling and significantly reduces the chances of material wastage or spillage.

The innovative design of our plant ensures a smooth and continuous flow of materials, enabling a higher production rate and eliminating delays. This translates into cost savings for our clients and enables them to meet tight project deadlines without compromising on quality.

Superior Performance and Precise Mixing

One of the key advantages of our belt conveyor concrete batching plant is its ability to deliver superior performance in terms of concrete mixing. The plant is equipped with high-quality mixers that ensure precise and consistent mixing of aggregates, cement, and water. This results in a homogenous and high-quality concrete mix that meets the specific requirements of each project.

The plant's advanced control system allows for accurate measurement and monitoring of ingredients, ensuring the right proportions are maintained at all times. This level of precision guarantees the production of concrete with optimal strength, durability, and workability, meeting the highest industry standards.

Flexibility and Customization Options

We understand that every construction project is unique, with specific requirements and constraints. That's why our belt conveyor concrete batching plant offers flexibility and customization options to cater to diverse project needs.

The plant can be easily configured to accommodate different types of aggregates, such as crushed stone, sand, or gravel. Additionally, it can be adapted to produce a wide range of concrete mixes, including regular concrete, specialty mixes, and even self-compacting concrete (SCC). This versatility allows our clients to produce the exact type of concrete required for their projects, ensuring optimal results every time.

Durability and Reliability

Investing in a belt conveyor concrete batching plant from Shengmao guarantees durability and reliability. We utilize high-quality materials and components in the construction of our plants, ensuring their long-lasting performance even in challenging operating conditions.

Our plants are designed to withstand heavy usage and harsh environments, providing our clients with a reliable solution that minimizes downtime and maintenance costs. This durability is essential for construction projects that demand consistent concrete production over extended periods.

Environmental Considerations

We recognize the importance of sustainability and environmental responsibility in the construction industry. Our belt conveyor concrete batching plant incorporates several features that contribute to a greener and more eco-friendly operation.

Efficient energy management systems and optimized water usage reduce resource consumption, minimizing the plant's ecological footprint. Moreover, our plant is designed to minimize dust emissions, ensuring a healthier working environment for operators and reducing air pollution on the construction site.

Welcome to choose our belt conveyor concrete batching plant!

Our belt conveyor concrete batching plant offers a host of benefits that make it the perfect choice for construction projects of all sizes. Its innovative design, enhanced efficiency, superior performance, and customization options set it apart from competitors. The plant's durability, reliability, and eco-friendly features further reinforce its value proposition.

Henan shengmao machinery Co.,ltd.'s belt conveyor concrete batching plant, you can expect seamless operations, consistent high-quality concrete production, and increased productivity. It is a testament to our commitment to delivering exceptional equipment that meets and exceeds the expectations of our clients.

Contact us today to discover how our belt conveyor concrete batching plant can elevate your construction projects to new heights of success.