Stationary Asphalt Mixing Plant

A Stationary Asphalt Mixing Plant is a complete set of equipment for producing high-quality asphalt mixtures for large-scale road and infrastructure projects. Unlike mobile asphalt plants, stationary plants are installed at fixed locations and offer higher production capacities, stability, and consistent quality for long-term projects like highways, expressways, airports, and bridges.

Key Features of Stationary Asphalt Mixing Plant

High Production Capacity: Designed for continuous and large-volume asphalt production.

Precision Control System: Equipped with advanced control panels for precise temperature, material ratio, and mixing control.

Reliable Operation: Rugged structure, wear-resistant components, and durable performance under harsh site conditions.

Environmentally Friendly: Includes advanced dust collection systems and noise reduction features for eco-friendly operation.

Customizable Configurations: Can be tailored with various capacity options (40-320 TPH) and component setups to suit specific project demands.

Main Applications

The Stationary Asphalt Mixing Plant is widely used in:

National and provincial highway projects

Airport runway construction

Municipal road engineering

Bridge and tunnel pavement

Urban road network maintenance

Large industrial park construction

How Stationary Asphalt Mixing Plant Works

The working process involves precise proportioning of aggregates, asphalt, and additives, followed by heating, drying, and thorough mixing in a high-capacity mixer. The final asphalt mixture is then stored in a finished product silo, ready for transportation to the paving site. The plant is equipped with a control room for real-time monitoring and management of production parameters, ensuring consistent quality output.

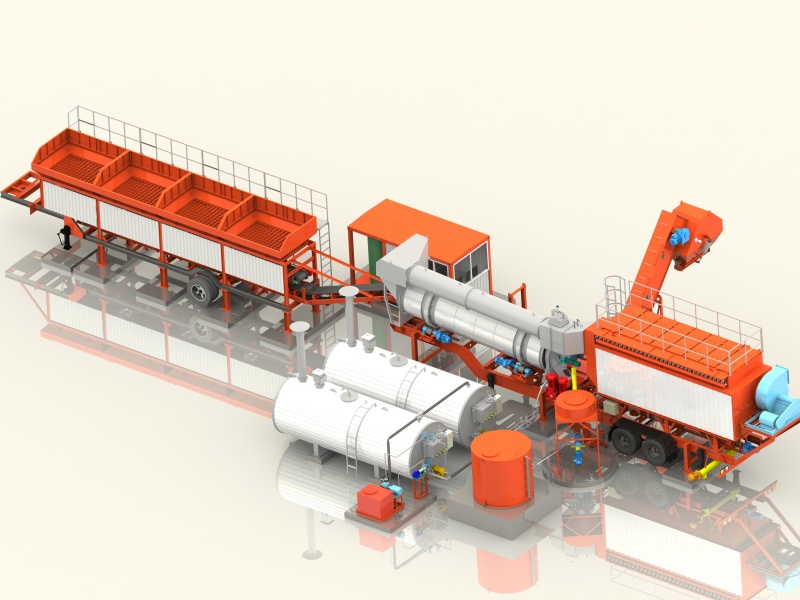

1. Compulsory type of stationary asphalt mixing plant is composed of the following parts:

1) Cold aggregate bin;

2) Slanted belt conveyor;

3) Aggregate drier;

4) Main burner;

5) Two level dust collector. Volute casing dust collector plus bag house dust collector or Cyclone dust collector plus water dust collector;

6) Hot aggregate elevator;

7) Powder elevator;

8) Bitumen system. Including bitumen tank, bitumen pump, heat conduction oil system, bitumen pipes etc.

9) Vibrating screen;

10) Aggreate trainsitional hopper and power transitional hopper;

11) Aggregate scale, bitumen scale and powder scale;

12) Twin-shaft mixer;

13) Control sytem (manual control and automatic control).

Looking for a reliable Stationary Asphalt Mixing Plant for your next project? Contact Henan Shengmao Machinery Co., Ltd. today and let us help you build better, faster, and more efficiently.

2. Drum type of stationary asphalt mixing plant is composed of the following parts:

1) Cold aggregate bin;

2) Slanted belt conveyor;

3) Aggregate drier;

4) Bitumen system. Including bitumen tank, bitmen pump and bitumen pipes;

5) Two level dust collector. Volute casing dust collector plus bag house dust collector or Cyclone dust collector plus water dust collector;

6) Finished product elevator;

7) Finished product bin.

3. Details of our stationary asphalt mixing plant.

1) Compulsory type of stationary asphalt mixing plant:

| Model | LB700 | LB1000 | LB1200 | LB1500 | LB2000 |

| Production Capacity (T/h) | 60 | 80 | 100 | 120 | 160 |

| Mixer Capacity (kg) | 750 | 1000 | 1200 | 1500 | 2000 |

| Dust Remove Effect (mg/Nm3) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| Fuel Consumption (kg/t) (Oil) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

| Fuel Consumption (kg/t) (Coal) | 10 | 10 | 10 | 10 | 10 |

| Aggregate Weighing Accuracy (%) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| Filler Weighing Accuracy (%) | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| Bitumen Weighing Accuracy (%) | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

2) Drum type of stationary asphalt mixing plant:

| Model | DHB20 | DHB40 | DHB60 | DHB80 | DHB100 |

| Production Capacity (T/h) | 20 | 40 | 60 | 80 | 100 |

| Mixing Type | Continuous | Continuous | Continuous | Continuous | Continuous |

| Dust Remove Effect (mg/Nm3) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Fuel Consumption (kg/t) (Oil) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

| Fuel Consumption (kg/t) (Coal) | 10-13 | 10-13 | 10-13 | 10-13 | 10-13 |

| Aggregate Weighing Accuracy(%) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 |

| Bitumen Weighing Accuracy(%) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Total Power (kw) | 50 | 75 | 128 | 165 | 200 |

4. International cases of our stationary asphalt mixing plant.

1) 60T/H stationary asphalt mixing plant in Russia