1. Without cement silo type of bag cement feeding system:

You have to make the arrangement to dump the cement in the powder form in to the feed hopper.

1) It is composed of a cement hopper and a screw conveyor;

2) work procedure: workers manually put cement bag into the cement hopper; the knives inside the hopper will break the cement bag and cement will be discharged into the hopper; the screw conveyor will deliver cement to cement scale on top of concrete mixer;

3) Features of this type of bag cement feeding system: cost-saving, easy to install, but there will be much dust discharged into the air;

4) Below are pictures of this type of bag cement feeding system.

Advantages of Bag Cement Feeding Systems

Increased Productivity

Automation reduces manual labor and speeds up feeding, increasing efficiency 2–3 times compared to manual handling.

Reduced Labor Intensity

Operators no longer need to handle heavy cement bags directly, reducing fatigue and workplace injuries.

Dust-Free Operation

Advanced dust collection ensures a clean working environment, meeting health and safety regulations.

Accurate Cement Measurement

Automatic weighing and dosing maintain consistent mix ratios, essential for high-quality concrete or mortar.

Enhanced Safety

Fewer manual operations reduce risks associated with lifting, spillage, and inhalation of cement dust.

Easy Maintenance

Modular design allows simple replacement and servicing of critical components, minimizing downtime.

Applications Across Industries

Ready-Mix Concrete Plants: Quickly feed cement into mixers for consistent concrete production.

Dry Mortar and Plaster Production: Automate the dosing of cement for stable product quality and higher output.

Cement Manufacturing Plants: Streamline batching and improve storage efficiency.

Construction Sites: Ideal for temporary or small-scale production setups requiring precise cement handling.

Choosing the Right System

When selecting a Bag Cement Feeding System, consider the following:

Feeding Capacity: Match the system to your daily production volume.

Bag Specifications: Ensure compatibility with standard cement bag weights (25kg, 50kg, or custom sizes).

Automation Level: Choose manual, semi-automatic, or fully automatic operation depending on budget and production needs.

Dust Control Requirements: High dust loads may require high-efficiency dust collectors.

Integration with Existing Equipment: Verify compatibility with current silos, mixers, or production lines.

Maintenance and Support: Check ease of maintenance, availability of spare parts, and service options.

Common Challenges and Solutions

Dust Leakage: Ensure the bag breaker is sealed properly and the dust collector is functional.

Material Blockage: Regularly clean conveyors and adjust screw or bucket elevator speeds.

Inaccurate Dosing: Calibrate weighing systems and sensors regularly for precise cement measurement.

For more information about bag cement feeding system and cement silo, please contact us.

5) If cement bag is too big to handle by workers, we can use a 2T hoist to work with this type of bag cement feeding system

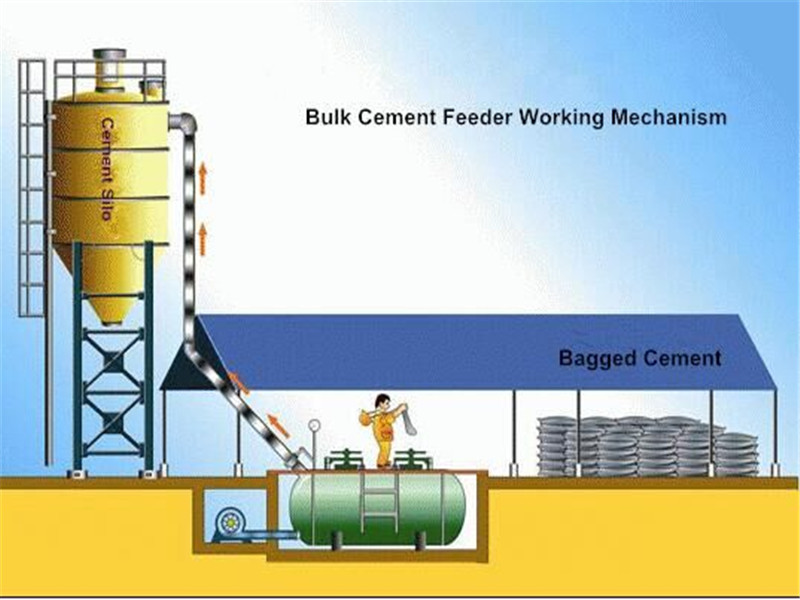

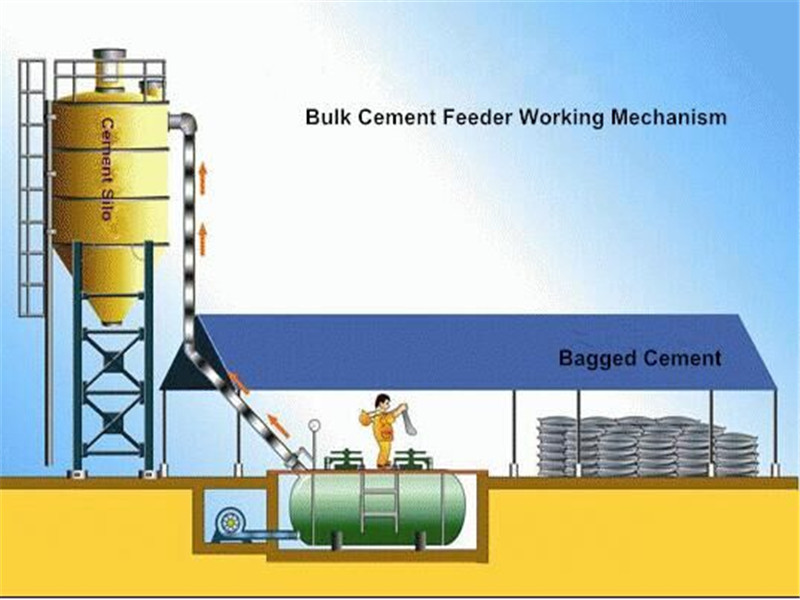

2. With cement silo type of bag cement feeding system. This type of bag cement feeding system can be devided into two types as well:

1) automatic type

A. It is composed of belt conveyor, cement bag breaker, screw conveyor and pneumatic cement feeder;

B. Work procedure: belt conveyor delivers cement bag to bag breaker, bag breaker breaks cement bag and cement will be discharged into bag breaker, screw conveyor delivers cement to pneumatic cement feeder which will deliver cement to cement silo;

C. Features of this type of bag cement feeding system: high efficiency and environment friendly, but very big bag cement can not be processed.

D. Below pictures are this type of bag cement feeding system.

2) manual type

A. It is composed of a cement hopper and a pneumatic cement feeder;

B. Work procedure: workers manually put cement bag into cement hopper (if cement bag is very big, we need to use forklift, wheel loader or a hoist), kinves inside the hopper will break cement bags, cement then is discharged into pneumatic cement feeder which will deliver cement to cement silo.

C. Features of this type of bag cement feeding system: cost-saving and big bag cement like 1 ton bag cement can be processed.

D. Below pictures are this type of bag cement feeding system.

3. working video of our automatic cement bag breaking and cement delivering machine.

4. International cases

1) Automaic bag cement feeding system delivered to Somaliland

2. Cement tank delivered to Philippines