1. Our vertical cement silo is composed of the following parts:

1) Vertical cement silo body which is usually made of carbon steel Q235;

2) Dust collector on the top of cement silo;

3) Safety valve;

4) Inside and outside ladders;

5) Level indicator;

6) Support legs;

7) Load cell on support legs;

8) Penumatic flow promotion device;

9) Manual butterfly valve;

10) Cement feeding pipe.

2. Features of our vertical cement silo:

1) Several measures are taken to make sure the cement silo is water-proof. Such as carbon dioxide welding, glass cement etc.

2) Primer and top coat are used to make sure the cement silo surface is antirust;

3) Safety valve is used to protect the cement silo when it is blocked and the inside pressure increases quickly;

4) Cement silo top dust collector is used to protect the environment;

5) Level indicators or load cell are used to let us know the quantity of cement inside cement silo;

6) Pneumatic flow promotion device is used to facilitates the discharging of cement;

7) Inside and outside ladders are equipped to help workers maintain the cement silo.

8) Our new technology can save much shipping space for clients (4 sets100t cement silo can be put into one 40FT container).

3. Delivery of cement silo:

1) For welding type cement silo, the Max. capacity that can be put into 40HQ container is 50T;

2) For bolted type cement silo, even 2000T cement silo can be put into container;

3) For welding type cement silo, if the capacity is more than 50T, we can use break bulk vessel or flat rack container to deliver it, but the cost is much more expensive than that of the 40HQ.

4. Details of our cement silo:

| Type | Bolted type or welding type |

| Capacity (T) | 20 to 2000 |

| Discharging Height | As per your requirements |

| Remarks | Accept customization |

Except from vertical cement silo, we also have horizontal cement silo which is very popular in recent years, because there is no need to make huge concrete foundation. Client can use it immediately after receiving it.

5. Pictures of welding type cement silo

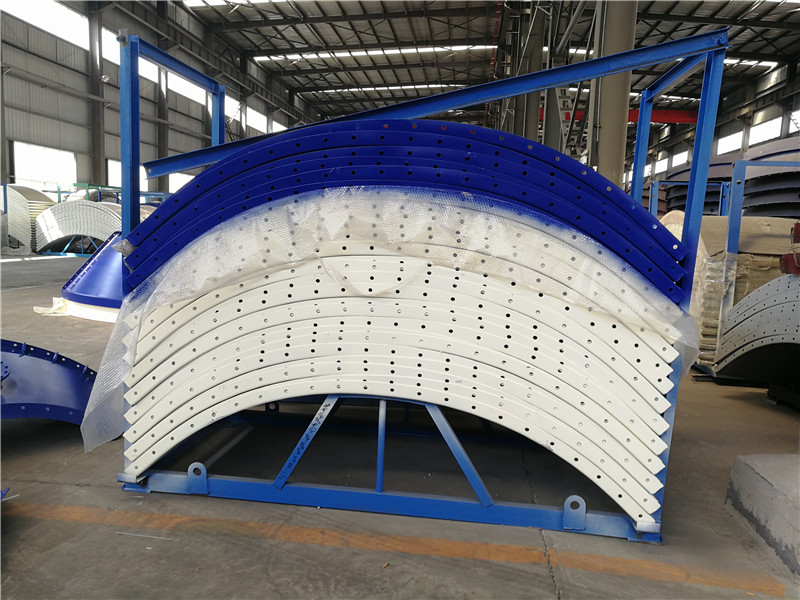

6. Pictures of bolted type cement silo

7. Pictures of our vertical cement silo on work site.

1) 100T, 200T and 300T cement silos installed in Philippine

2) 50T cement silo installed in Thailand

3) 500T cement silo installed in Russia

4) 2000T cement silo installed in New Zealand

5) 1000T cement silo to Ethiopia

6) 400T cement silo to South Korea

8. Videos of our vertical cement silo:

1) Video of our 1000T cement silo